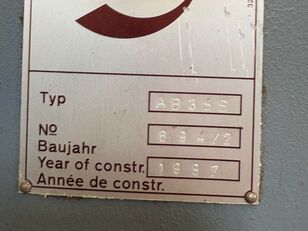

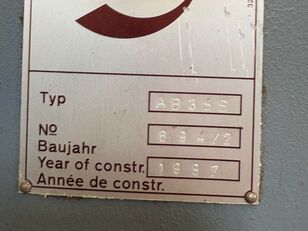

Alzmetall Altmetall AB 35 S drilling machine for sale by auction

≈ GHS 5,997

If you decide to buy equipment at a low price, make sure that you communicate with the real seller. Find out as much information about the owner of the equipment as possible. One way of cheating is to represent yourself as a real company. In case of suspicion, inform us about this for additional control, through the feedback form.

Before you decide to make a purchase, carefully review several sales offers to understand the average cost of your chosen equipment. If the price of the offer you like is much lower than similar offers, think about it. A significant price difference may indicate hidden defects or an attempt by the seller to commit fraudulent acts.

Do not buy products which price is too different from the average price for similar equipment.

Do not give consent to dubious pledges and prepaid goods. In case of doubt, do not be afraid to clarify details, ask for additional photographs and documents for equipment, check the authenticity of documents, ask questions.

The most common type of fraud. Unfair sellers may request a certain amount of advance payment to “book” your right to purchase equipment. Thus, fraudsters can collect a large amount and disappear, no longer get in touch.

- Transfer of prepayment to the card

- Do not make an advance payment without paperwork confirming the process of transferring money, if during the communication the seller is in doubt.

- Transfer to the “Trustee” account

- Such a request should be alarming, most likely you are communicating with a fraudster.

- Transfer to a company account with a similar name

- Be careful, fraudsters may disguise themselves as well-known companies, making minor changes to the name. Do not transfer funds if the company name is in doubt.

- Substitution of own details in the invoice of a real company

- Before making a transfer, make sure that the specified details are correct, and whether they relate to the specified company.

Seller's contacts

• Drilling performance:

• In steel: Ø 32 mm

• In cast iron: Ø 45 mm

• Drilling capacity (projection): 300 mm

• Spindle stroke (Pinol stroke): approx. 160–175 mm

• Spindle holder: MK 4

• Speed range: Infinitely variable approx. 65–1,750 rpm

• Automatic feed: Three levels – 0.1 / 0.2 / 0.3 mm/rev

• Table dimensions:

• Table surface: around 500 × 370 mm

• Designed for 600 × 470 mm total area

• T-slots: Two grooves, approx. 14 mm wide, spacing approx. 224 mm

• Column diameter: 140–145 mm

• Distance from spindle to table: approx. 706 mm

• Distance from spindle to base plate: approx. 1,165 mm

• Bohrleistung:

• In Stahl: Ø 32 mm

• In Guss: Ø 45 mm

• Bohrvermögen (Ausladung): 300 mm

• Spindelhub (Pinolhub): ca. 160–175 mm

• Spindelaufnahme: MK 4

• Drehzahlbereich: Stufenlos etwa 65–1 750 U/min

• Automatischer Vorschub: Drei Stufen – 0,1 / 0,2 / 0,3 mm/U

• Tischmaße:

• Tischfläche: rund 500 × 370 mm

• Ausgelegt auf 600 × 470 mm Gesamtfläche

• T-Nuten: Zwei Nuten, ca. 14 mm breit, Abstand ca. 224 mm

• Säulendurchmesser: 140–145 mm

• Abstand Spindel–Tisch: ca. 706 mm

• Abstand Spindel–Grundplatte: ca. 1 165 mm

In Stahl: Ø 32 mm

In Guss: Ø 45 mm

Bohrvermögen (Ausladung): 300 mm

Spindelhub (Pinolhub): ca. 160–175 mm

Spindelaufnahme: MK 4

Drehzahlbereich: Stufenlos etwa 65–1 750 U/min

Automatischer Vorschub: Drei Stufen – 0,1 / 0,2 / 0,3 mm/U

Tischfläche: rund 500 × 370 mm

T-Nuten: Zwei Nuten, ca. 14 mm breit, Abstand ca. 224 mm

Säulendurchmesser: 140–145 mm

Abstand Spindel–Tisch: ca. 706 mm

Abstand Spindel–Grundplatte: ca. 1 165 mm

Marke: Altmetall

Länge: 1070

Höhe: 1880

Breite: 650

Technische Merkmale

Bohrleistung

Tischmaße

Ausgelegt auf 600 × 470 mm Gesamtfläche

techniques

• Performances de forage :

• En acier : Ø 32 mm

• En fonte : Ø 45 mm

• Capacité de perçage (projection) : 300 mm

• Course de la broche (course Pinol) : env. 160–175 mm

• Porte-broche : MK 4

• Plage de vitesse : réglable en continu env. 65–1 750 tr/min

• Alimentation automatique : Trois niveaux – 0,1 / 0,2 / 0,3 mm/tr

• Dimensions de la table :

• Surface de la table : environ 500 × 370 mm

• Conçu pour une surface

totale de 600 × 470 mm

• rainures en T : deux rainures d’environ 14 mm de large, espacement d’environ 224 mm

• Diamètre de la colonne : 140 à 145 mm

• Distance entre la broche et la table : environ 706 mm

• Distance entre l’axe et la plaque de base : env. 1 165 mm

tecniche

• Prestazioni di perforazione:

• In acciaio: Ø 32 mm

• In ghisa: Ø 45 mm

• Capacità di foratura (sporgenza): 300 mm

• Corsa del mandrino (corsa Pinol): circa 160–175 mm

• Portamandrino: MK 4

• Gamma di velocità: Variabile in continuo circa 65–1.750 giri/min

• Avanzamento automatico: Tre livelli – 0,1 / 0,2 / 0,3 mm/giro

• Dimensioni del tavolo:

• Superficie del tavolo: circa 500 × 370 mm

• Progettato per un'area

totale di 600 × 470 mm

• Scanalature a T: due scanalature, larghe circa 14 mm, interasse circa 224 mm

• Diametro colonna: 140–145 mm

• Distanza dal mandrino alla tavola: circa 706 mm

• Distanza dal mandrino alla piastra di base: circa 1.165 mm

• Boorprestaties:

• In staal: Ø 32 mm

• In gietijzer: Ø 45 mm

• Boorcapaciteit (uitval): 300 mm

• spindelslag (Pinol-slag): ca. 160–175 mm

• Spindel houder: MK 4

• Toerentalbereik: traploos ca. 65–1.750 tpm

• Automatische voeding: drie niveaus – 0,1 / 0,2 / 0,3 mm/omw

• Afmetingen tafel:

• Tafeloppervlak: ca. 500 × 370 mm

• Ontworpen voor een totale oppervlakte

van 600 × 470 mm

• T-gleuven: twee groeven, ca. 14 mm breed, afstand ca. 224 mm

• Diameter kolom: 140-145 mm

• afstand van spindel tot tafel: ca. 706 mm

• afstand van spindel tot voetplaat: ca. 1.165 mm